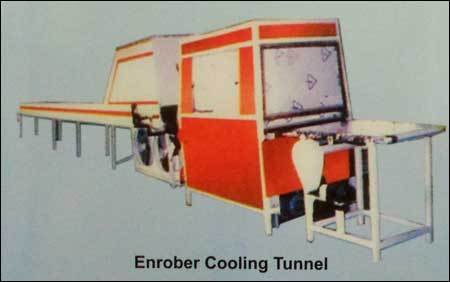

The Enrober Cooling Tunnel is a specialized machine designed for the efficient cooling and setting of chocolate-coated, enrobed, or glazed products. It is widely used in the confectionery, bakery, and snack industries to ensure a perfect finish on products by providing uniform cooling. The tunnel maintains controlled temperature and airflow to ensure that coatings are set evenly, preventing defects like melting, smudging, or uneven textures.

Key Features of Enrober Cooling Tunnel

- High-efficiency cooling system for quick and uniform setting of enrobed products.

- Adjustable temperature and airflow controls for different product requirements.

- Made from high-grade stainless steel for hygiene and durability.

- Modular and customizable design to suit various production line configurations.

- Low noise and energy-efficient operation.

- Easy-to-clean design with removable parts for better maintenance.

- Conveyor belt system to handle products smoothly and prevent damage during cooling.